Lathe Accidents In Russia: Safety Lessons & Prevention Strategies

In the realm of industrial mishaps, do you know which incidents serve as grim reminders of the ever-present need for stringent safety protocols? Accidents involving heavy machinery, particularly those involving lathes, highlight the critical importance of meticulous training, unwavering adherence to safety regulations, and the absolute necessity of a comprehensive understanding of machine operations.

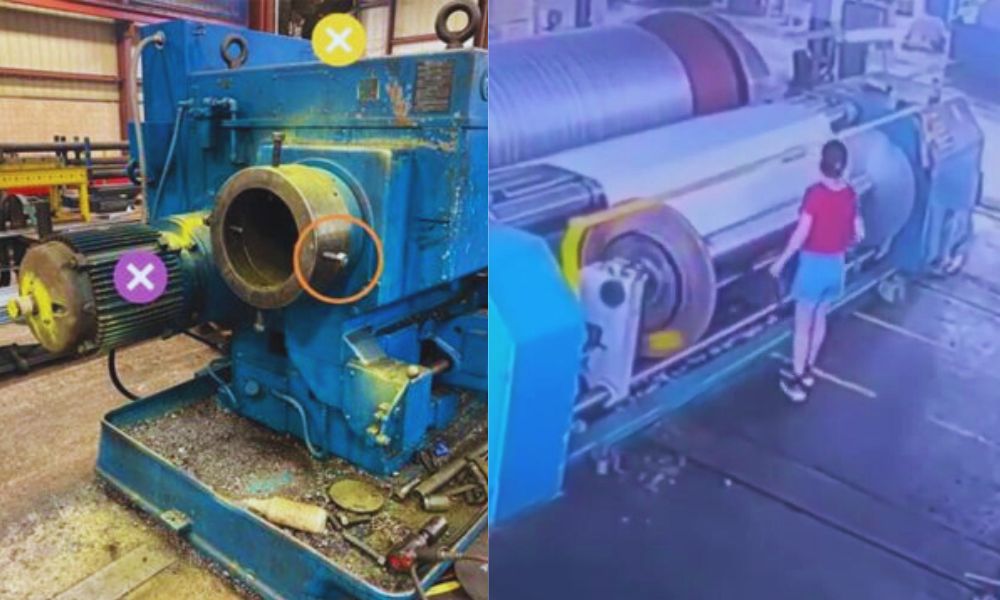

The phrase "Russian lathe accident" immediately conjures images of severe industrial incidents, often marked by devastating injuries or, tragically, fatalities. These events, which have occurred in manufacturing facilities across Russia and beyond, serve as sobering case studies in the consequences of inadequate safety measures and the potential dangers inherent in operating complex machinery. The core issues typically revolve around a combination of factors: improper handling of the equipment, a blatant disregard for established safety protocols, and, sometimes, a reckless disregard for the inherent risks involved.

A lathe machine, at its core, is a sophisticated tool used for shaping materials like metal, wood, and plastic. It functions by rotating a workpiece against a cutting tool, allowing for precise removal of material to achieve a desired shape. This process, while essential for manufacturing, poses inherent risks if not managed correctly. The rotating parts, the potential for flying debris, and the power involved all contribute to the potential for serious injury.

To fully grasp the implications of these accidents, it is essential to delve into their multifaceted nature, considering both the technical aspects of the machinery and the human factors that contribute to these tragic events. We examine the operational settings, the procedures in place, and the human element within the context of the incidents, providing a comprehensive analysis that underscores the importance of safety education and practices.

These accidents are frequently attributed to several underlying causes. One common factor is a lack of adequate training or insufficient understanding of the lathe's operating procedures. Without comprehensive training, workers may inadvertently make mistakes, misjudge settings, or fail to recognize potential hazards. Another critical cause is a failure to adhere to established safety protocols. These protocols, which may include the use of protective equipment, the proper guarding of moving parts, and the implementation of lockout/tagout procedures, are specifically designed to mitigate risks and prevent accidents. Often, however, these protocols are either ignored or inadequately enforced.

Heres a brief table summarizing some of the essential aspects of lathe machine safety in Russian manufacturing facilities, keeping in mind that the exact legal framework can vary:

| Aspect | Details |

|---|---|

| Legal Framework | Primarily governed by federal laws and regulations concerning labor protection and industrial safety. These laws mandate the establishment of safety standards, accident investigation procedures, and worker training programs. Specific regulations relating to the use and maintenance of machinery, including lathes, are crucial. |

| Safety Standards | Safety standards typically cover various aspects, including:

|

| Worker Training and Certification | Comprehensive training programs are vital, covering:

|

| Enforcement and Oversight | Responsibilities for enforcing safety regulations typically fall on:

|

| Accident Investigation | Detailed investigations are conducted following any industrial accident. These investigations aim to determine the root causes, identify any safety failures, and recommend corrective actions to prevent similar incidents in the future. Findings are often used to update safety protocols, training programs, and equipment design. |

To learn more about Russian labor laws and industrial safety, you can refer to the official website of the Federal Labor and Employment Service of Russia. (Note: Please ensure that you have the latest information from official sources regarding the legal framework). You can find more information on that site here.

Furthermore, the accident serves as a stark reminder of the consequences of neglecting established safety practices. The emotional and psychological toll on those involved, including the injured workers and their families, should never be underestimated. In addition, there are the economic costs, including medical expenses, lost productivity, and potential legal liabilities. In many cases, accidents are caused by a "skittish grasp of safety measures," resulting in injuries that are devastating. Without comprehensive understanding, workers are at risk of severe harm.

By delving into the specifics of the Russian lathe accidents, we can better comprehend how such tragedies can be averted in the future. This can be achieved by thoroughly investigating the circumstances surrounding each incident. The aim is to understand the sequence of events, the mechanical failures, the environmental factors, and the human actions that culminated in the accident. This includes looking closely at the equipment involved, the working environment, the worker's experience, and the training they had received.

Addressing these causes necessitates a multi-pronged approach. First, enhancing worker training is essential. Training programs should be comprehensive, hands-on, and regularly updated to reflect the latest safety standards and equipment advancements. Workers should not only understand the mechanics of lathe operation but also be thoroughly familiar with hazard identification and risk assessment. Second, the strict enforcement of safety protocols is crucial. This includes ensuring the consistent use of personal protective equipment (PPE), proper guarding of machinery, and the implementation of robust lockout/tagout procedures. Regular inspections and audits can help ensure that safety protocols are followed.

In addition to individual training and adherence to safety measures, systemic improvements can also play a role. These might include the adoption of safer machine designs, the implementation of more advanced safety technologies (such as sensors and automated safety systems), and the fostering of a strong safety culture within the workplace. A positive safety culture is one where safety is valued by everyone, from management to line workers, and where there is open communication about safety concerns.

By understanding the causes of lathe accidents and implementing effective safety measures, it is possible to create safer working environments. This involves rigorous training, the consistent application of safety protocols, and a corporate culture that prioritizes safety. It is also important to keep in mind that understanding the details of past incidents is critical to preventing future tragedies. By learning from the Russian lathe accident, we can strengthen safety practices, protect workers, and ensure that workplaces remain safe environments.

These accidents can have severe consequences, affecting not only the individuals directly involved but also the broader industrial environment. This is crucial reminder of the potential dangers associated with industrial equipment, particularly lathes, which are commonly used in manufacturing and machining processes. The Russian lathe incident is a topic of significant discussion in recent years, especially in the context of workplace safety and industrial accidents. Accidents involving heavy machinery (such as lathes) underscore the importance of proper training and adherence to safety protocols.

To avoid future accidents, it is essential to comprehend the contributing factors. This highlights the significance of proper training and adherence to safety protocols by analyzing the particulars of the incident and pointing out areas where safety measures were lacking. This incident gained significant attention due to the unforeseen consequences it brought about. The Russian lathe accident highlights the critical need for robust safety measures in industrial settings.

The incident involving a lathe in Russia reveals the need for a thorough examination of manufacturing practices and potential safety hazards. These incidents, which are often the result of inadequate training, a failure to follow established safety protocols, or a general lack of awareness of the hazards involved, can result in serious injuries or even fatalities. By understanding the causes of these accidents, manufacturers and safety professionals can take proactive measures to prevent similar incidents from occurring in the future. These steps include providing comprehensive training for workers, implementing and enforcing strict safety protocols, and conducting regular inspections to identify and mitigate potential hazards.

We encourage you to share this article with your colleagues and peers to raise awareness about the risks of lathe operations and the importance of safety. Industrial accidents, such as the infamous Russian lathe accident, have long served as stark reminders of the importance of workplace safety.